When purchasing a custom charger, price, functional requirements, quality control, production cycle and delivery, after-sales service and warranty are the key factors you care about most. We will answer these questions in detail in the FAQs section. If you have any other questions, please feel free to contact us.

In a broad sense, there are many factors that affect the cost and price of mobile phone chargers, including technology, materials, market strategies and external environment. In a narrow sense, taking the current mainstream fast charging charger as an example, the main factors affecting its cost are the choice of main control chip, transformer/capacitor, Gan technology/traditional silicon technology. Our main hot-selling products are gallium nitride 33w, 67w and 100w chargers, which use gallium nitride technology and are equipped with world-renowned chips such as Power Integrations and Innoscience. In addition, we also have more cost-effective Southchip and Meraki Intecrated to choose from.

As of March 2025, Apple's latest iPhone15 series all support the PD3.0 fast charging protocol, with corresponding power of 45w Max (15V 3A). MacBook Pro 14" standard configuration 70w, maximum support 96w. Macboo Pro 16" standard configuration 100w, maximum support 140w. Samsung Galaxy S25 Ultra and S25+ support PPS protocol (within PD protocol), maximum support 45w. S25 supports up to 25w. For more detailed information on product models, power specifications and fast charging protocols, please visit our Industry News page, or contact us directly for detailed product forms.

Our charger production quality control process consists of IQC (Incoming Quality Control) incoming material inspection, FQC (Final Quality Control) online inspection, IPQC (In-Process Quality Control) inspection, PQE (Product Quality Engineer) on-line inspection, and OQC (Outgoing Quality Control) finished product inspection. These inspection links and quality control positions are different stages to ensure product quality. Each link is crucial and complements each other to ensure that every link from raw material procurement to final finished product delivery meets quality requirements. For more details, please visit our Industry News page or contact us directly for information.

We provide a 2-year product warranty period, starting from the date of manufacture. If the quality failure is determined to be caused by the product after testing by our company, you can effectively enjoy the warranty service (random accessories are not covered by the warranty), and you can enjoy return, exchange and repair services based on your actual evaluation of the product.

We are honored to offer you samples,the sample charge and shipping cost will be paid by buyer. We can refund the money when you place the order.

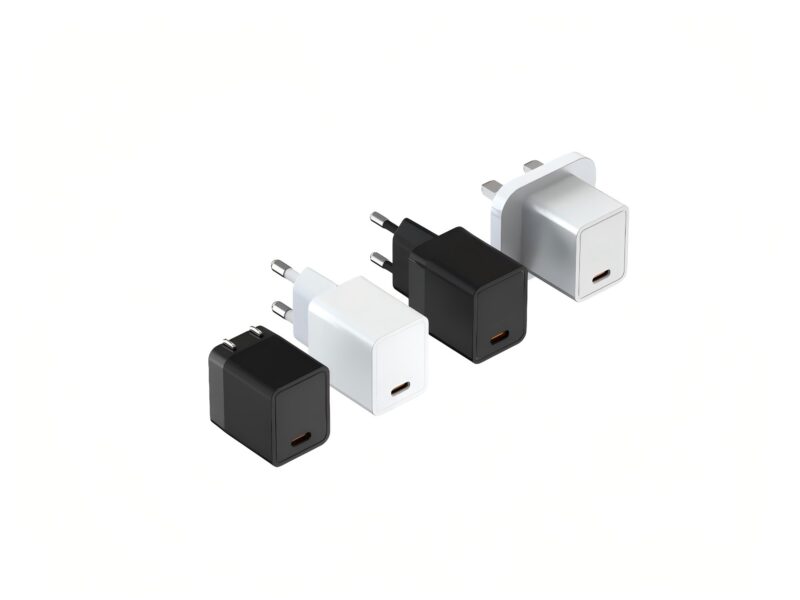

We did ETL for US, SAA for AU, PSE for Japan, CE for EU, CB etc.

Different products have different requirements, which can be negotiated. We will do our best to meet your needs and reduce your inventory risk.

If ready stock, the leadtime is within 3~7days. If new production, it will be around 25~45days depends on your different production requirments.

TT, LC.